Peter Zelinski Editor-in-Chief

Peter Zelinski is the founding editor of Additive Manufacturing magazine and Additive Manufacturing Media, which for over 10 years has reported on industrial 3D printing and its adoption by manufacturers. As the brand’s editor-in-chief, Pete is exploring the advance of 3D printing as a means of production, and the ways it is changing both part design and manufacturing enterprises. He has been a regular speaker at the Additive Manufacturing Conference, which is now the Formnext Forum, and he is co-creator and co-host of the video series on 3D printing for part production, The Cool Parts Show — a show that has been honored with a national award for Best Use of Video in niche media. He is a podcaster, appearing regularly with Additive Manufacturing Media colleagues in AM Radio, and he has also appeared in a sister podcast, Made in the USA. In 2020, he was co-host of the U.S. Air Force’s week-long event aimed at manufacturing for military readiness and sustainment, the Advanced Manufacturing Olympics. Pete also serves as editorial director of Modern Machine Shop, a sister publication focused on metalworking and CNC machining, and the magazine he has been part of for over 25 years. He holds a degree in mechanical engineering from the University of Cincinnati.

Video: AM for Repair of Large Shafts

Wind power shafts that might once have been scrapped are now returned to service. See the robotic directed energy deposition (DED) and shaft preheating system developed by Ikergune, Izadi and Talens.

Watch3 Attributes of the “Second Wave” of AM Part Producers

Successful contact manufacturers in additive look more and more like successful contract manufacturers in general.

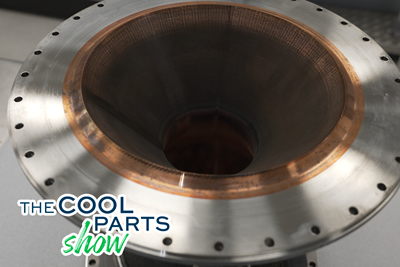

Read More3D Printed NASA Thrust Chamber Assembly Combines Two Metal Processes: The Cool Parts Show #71

Laser powder bed fusion and directed energy deposition combine for an integrated multi-metal rocket propulsion system that will save cost and time for NASA. The Cool Parts Show visits NASA’s Marshall Space Flight Center.

WatchCryogenic Tanks for Space Refueling: The Cool Parts Show All Access

NASA's Paul Gradl describes an important application of AM beyond the spacecraft itself: refueling the spacecraft. Directed energy deposition offers the most practical way to produce aluminum tanks to keep fuel supercool.

WatchHow to Rapidly Calibrate 4-Laser Production LPBF Machines

Multi-laser machines introduce an additional source of variation; the separate lasers have to synch with one another. At this Indiana additive manufacturer, one-third of the laser powder bed fusion machines are multi-laser. Here is is the AM calibration tool this company uses.

Read MoreFreeform: Binder Jetting Does Not Change the Basics of Manufacturing

Rather than adapting production methodologies to additive manufacturing, this Pennsylvania contract manufacturer adapts AM to production methodologies. In general, this starts with conversation.

Read MoreVideo: Binder Jetting Production Workflow at Freeform Technologies

Additive manufacturing via binder jetting includes a sequence of downstream steps. During a visit to the Pennsylvania metal 3D printing part producer, I had the chance to walk through this process.

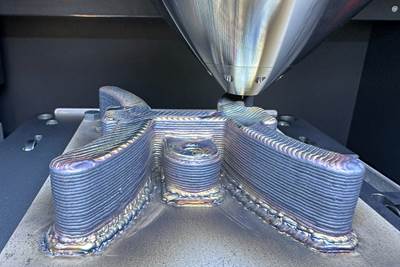

WatchHow Machining Makes AM Successful for Innovative 3D Manufacturing

Connections between metal 3D printing and CNC machining serve the Indiana manufacturer in many ways. One connection is customer conversations that resemble a machining job shop. Here is a look at a small company that has advanced quickly to become a thriving additive manufacturing part producer.

Read MoreSouthern Indiana’s Thriving AM Part Producer — What I Saw at Innovative 3D Manufacturing: AM Radio #49

Recorded just after the visit to the laser powder bed fusion contract manufacturer, here is a conversation exploring observations and impressions of this company and its metal 3D printing work.

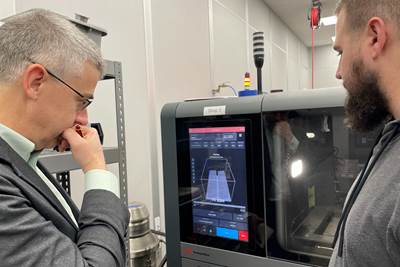

ListenPush-Button DED System Aims for Machine Shop Workflow in Metal AM

Meltio M600 metal 3D printer employs probing, quick-change workholding and wire material stock to permit production in coordination with CNC machines.

Read MoreUltra-Complex 3D Printed Scaffolds Enable Cell Growth: The Cool Parts Show #70

Perhaps the ultimate surface-area challenge is in bioengineering: creating structures that can grow sufficient cells within a compact volume to be effective for leading-edge medical treatments. The Southwest Research Institute develops bioreactor scaffolds that could only be made using 3D printing.

WatchImplicit Modeling and Metamaterials: The Cool Parts Show All Access

Metafold CEO Elissa Ross describes one of the promises of more effective modeling of geometrically complex 3D printed forms: expanded use of metamaterials. To what extent can material “properties” come from geometry rather than the material itself?

Watch

.png;maxWidth=300;quality=90)